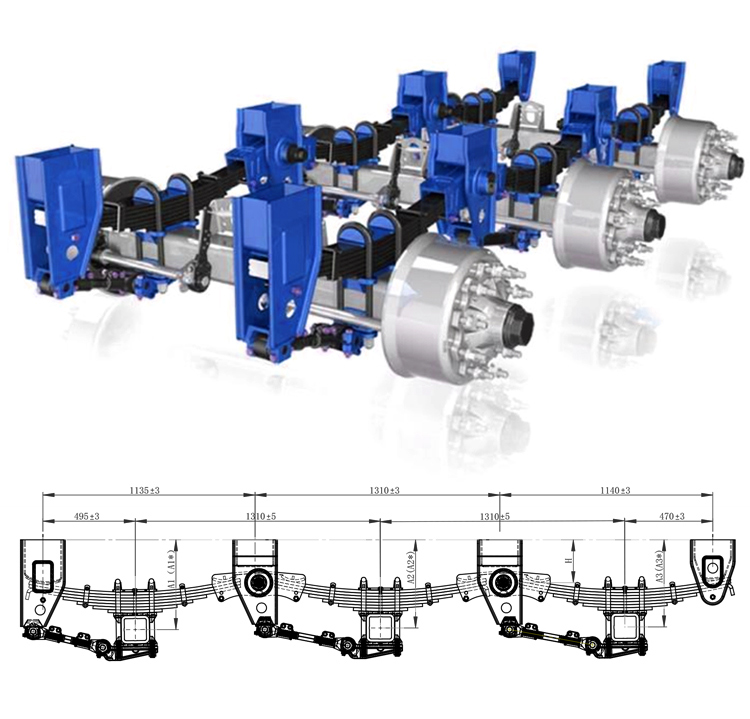

13T Leaf spring trailer axle

Leaf spring trailer axle as a special elastic element, leaf spring structure is widely used in corresponding automotive suspensions, which can be divided into multi leaf spring suspension and small leaf spring suspension: multi leaf spring suspension has simple structure and low cost; The small leaf spring suspension consists of several longitudinal leaf springs, dual cylinder hydraulic shock absorbers, lateral stabilizer bars, buffer blocks, and other components. Compared to air suspension systems, it has the advantages of low cost, simple structure, good performance, high reliability, and long service life.

Equalizer bush: bronze/mixed material

Hanger thickness: 6MM,8MM for option

Equalizer thickness: 10MM,12MM for option

Torque arm: 28mm,36mm

Products Description

Leaf spring trailer axle,commonly known as leaf springs and steel plate bridges, they are mainly composed of leaf springs, suspension bearings (commonly known as lifting lugs), connecting rods, U-bolts, and other components. Their obvious advantages are simple structure, low cost of construction and maintenance, stronger rigidity, and higher bearing capacity. Leaf springs have a guiding function that can transmit forces and moments in various directions. The springs can also exhibit linear or nonlinear elastic characteristics in certain combinations, so they are still widely used in medium or heavy transport vehicles.

Working principle of leaf spring suspension:

When the vehicle is traveling on uneven road conditions, the wheel bumps drive the axle to jump up, and the leaf spring and the lower end of the shock absorber move up simultaneously. The length of the leaf spring will increase during upward movement, which is coordinated by the extension of the lifting lug; Due to the fixed upper end of the shock absorber, when the lower end moves up, it is equivalent to being in a compressed state, increasing damping and attenuating vibration. When the jumping momentum on the axle exceeds the distance between the buffer block and the stop block, the buffer block contacts the stop block and compression occurs.

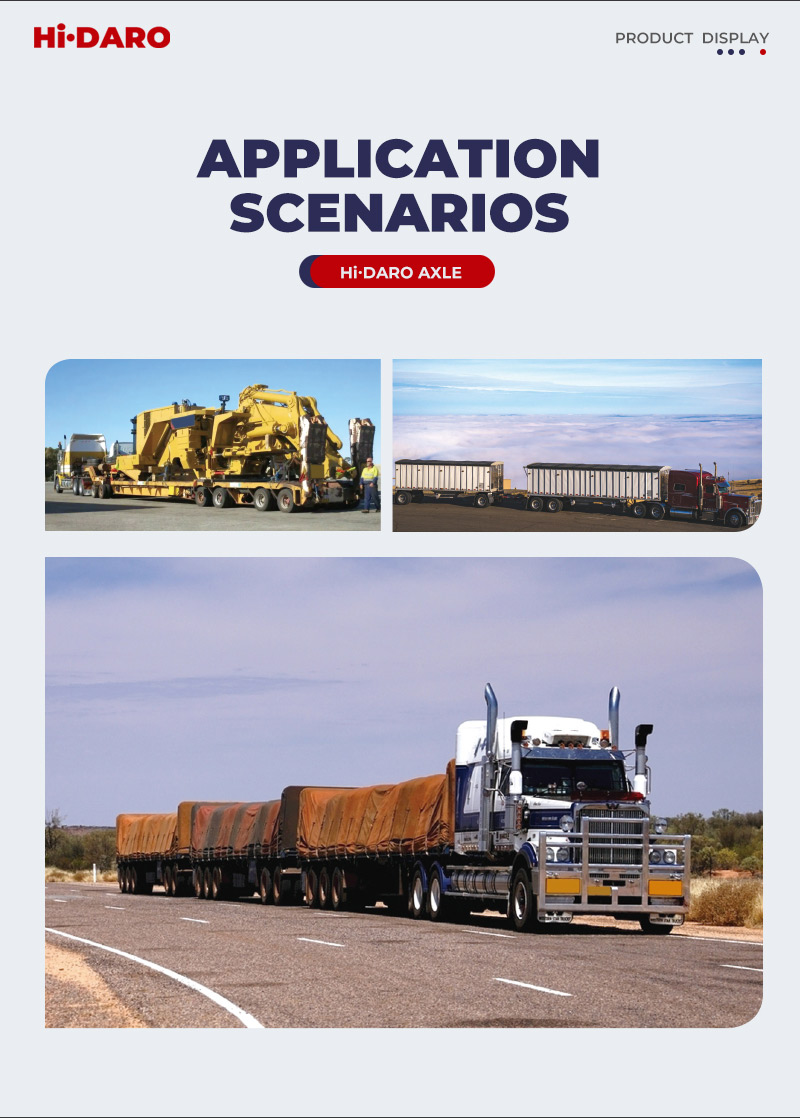

Application Scenario

Leaf spring trailer axle is suitable for heavy trailers with goods that are not particularly afraid of collision, such as trailers transporting wood, steel coils, coal, and gravel. Car owners should try to choose plate springs produced by regular brands. After all, suspension is directly related to the load bearing of the vehicle, especially for heavy-duty vehicles. It is better to be cautious when selecting products.

Package & Delivery